Introduction to the Laboratory: :

PSN Laboratory began its activities in 2011, measuring parameters related to bearings in an area of approximately 150 square meters at the factory site. PSN laboratories serve as the reference center for measuring various types of bearings and roller bearings in Iran. This laboratory, in providing these services to customers, is committed to adhering to legal requirements and common technical practices to ensure continuous improvement in performance, reliability of results, and traceability of calibration and test data. This is achieved by offering high-quality laboratory services and employing standard procedures and methods, and for this purpose, the ISO/IEC 17025 standard has been established and maintained.

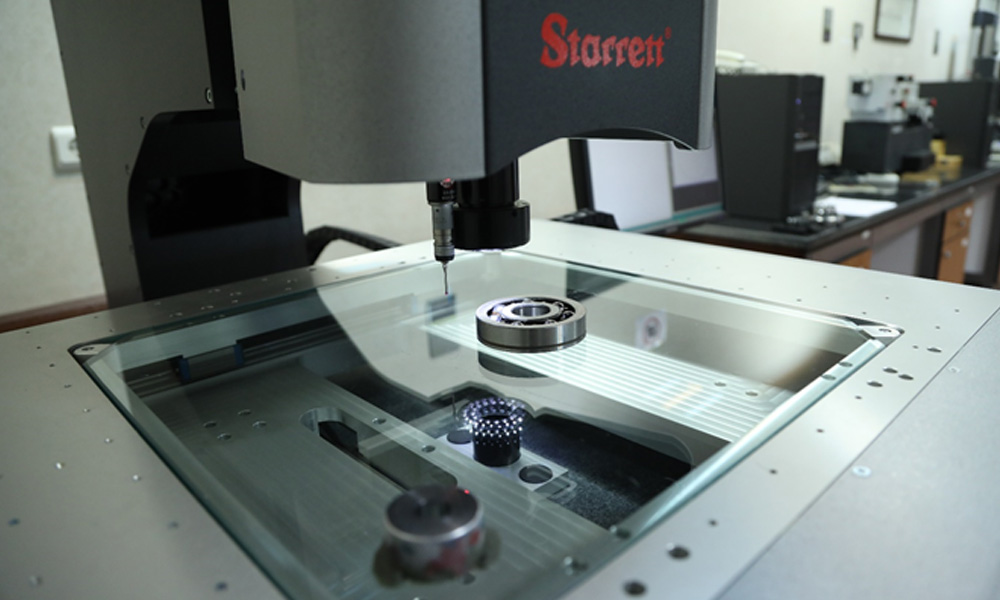

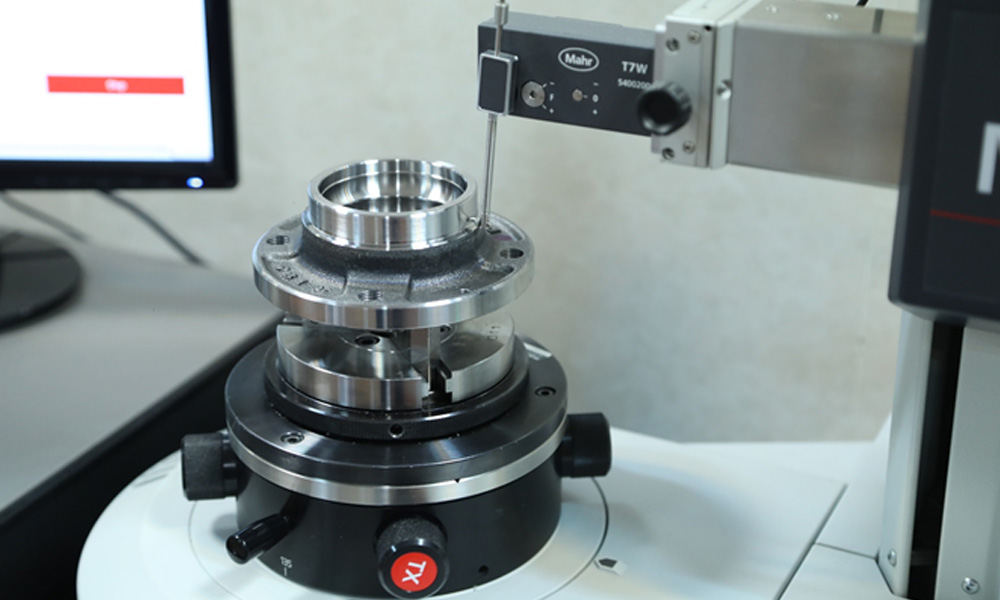

Metrology Laboratory:

The Metrology Laboratory aims to achieve the highest quality measurement results on bearings. Measurement equipment were purchased from reputable American and German brands including:VMM/CMM machine from USA, brand Starrett with 0.1 µm resolution

ULM 300 machine from Germany, brand Mahr, with 0.01 µm resolution, capable of measuring internal and external diameters and thickness.

UD 120 machine from Germany, brand Mahr, for measuring surface roughness, profile and contour shape with resolution: 0.01 µm, Roughness: 1 nm.

MMQ200 machine from Germany, brand Mahr, for measuring roundness and form geometrical tolerances with 0.01 µm resolution.

Functional Testing Laboratory:

To measure the functional parameters of bearings, the following devices are used:

Axial Clearance Measurement Device with a probe from Germany, brand Mahr, with 0.01 µm resolution.